Packing of Toyopearl AF-r Protein a HC-650F

PACKING OF TOYOPEARL AF-r PROTEIN A HC-650F IN PROCESS SCALE COLUMNS

TOSOH

Application n°a15p64a

TOYOPEARL AF-rProtein A HC is an ultra-high capacity resin for affinity purification of immunoglobulins. Particle size, porosity of the base material, as well as ligand composition and density was optimized with the aim to reach maximum binding capacity. The resulting resin offers a typical binding capacity of 70 g/L resin at 5 minutes residence time. The binding capacity is only slightly decreased when reducing the residence time/increasing linear flow.

The high binding capacity of the resin at short residence times allows using short bed heights and high flow rates. However, due to the relatively small particle size of 45 µm flow rates need to be adapted to the pressure limitations of the system/column hardware.

In order to determine the optimum conditions for packing and using this resin in process scale columns we evaluated conditions for various column dimensions and manufacturers.

MATERIAL AND METHODS

COLUMN HARDWARE:

A: 20 cm ID Quikscale® (QS 200), 10 µm mesh size, max.0.6 MPa, MerckMillipore

B: 40 cm ID Resolute® 400 self-packer, 20 µm mesh size, max. 0.5 MPa, Pall Corporation

C: CA-601S radial flow column with 6 cm bed height, 5 L bed volume, 10 µm mesh size, Proxcys B.V.

PACKING PROCEDURE

A (QS 200): Slurry concentration 40 - 50 %; Packing was performed according to the TOYOPEARL Instruction Manual:

Flow was increased stepwise, starting with 50 cm/h over 100 cm/h to 200 cm/h before lowering the piston to the top of the bed. For final bed compression the flow was increased stepwise again starting from 100 cm/h to 300 cm/h (or reaching max. 0.4 MPa) before lowering the piston 2 - 3 mm into the final bed.

B (Resolute 400): Slurry concentration: 30 - 40 %; Slurry transfer was performed with a diaphragm packing pump into the column at constant ~0.45 MPa pneumatic pressure. The packing speed of initially ~2,000 cm/h went down to 100 cm/h during bed formation. Flow packing: stepwise flow increase with process pump (∆50 cm/h/min until max system pressure). Piston was lowered 2 mm into the bed.

C (CA-601S): Slurry concentration 30 - 50 %; Slurry transfer and packing with system pump into the column (∆p~0.3 MPa); packing speed ~600 cm/h.

COLUMN TESTING

Bed stability was tested in water, 1 M NaCl and 3 M NaCl (to mimic mAb feedstock application) as a mobile phase. Packing performance was evaluated by injecting 50 mL of 5 % acetone (UV detector) or salt (conductivity detector) at 100 cm/h.

RESULTS

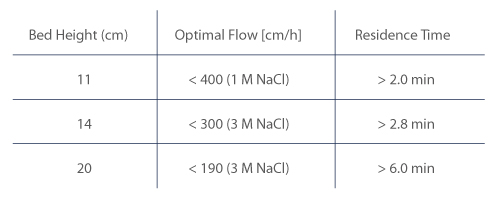

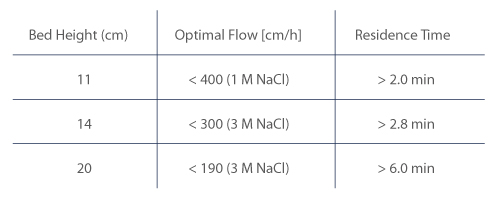

Table 1 shows optimal flow rates/residence times for various bed heights in a 20 cm ID QuikScale column. Up to a bed height of 15 cm a residence time of up to 2 -3 min is feasible. For higher bed heights such as 20 cm the residence time should be increased to > 5 minutes which simultaneously allows exploiting the maximum binding capacity of the resin.

Packing qualities of 4,000 - 6,000 theoretical plates per meter for the unretained peak and symmetry values of 1.1 – 1.7 were obtained throughout all packing tests at various bed heights (~ 20 different experiments in total).

TABLE 1_FLOW RECOMMENDATIONS FOR VARIOUS BED HEIGHTS

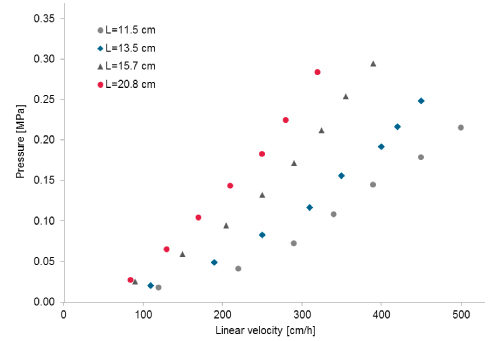

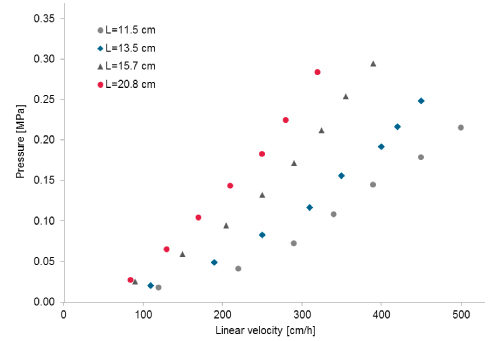

Figure 1 shows the pressure flow curves in water as mobile phase for various bed heights for the 200 mm ID QuickScale column.

FIGURE 1_PRESSURE FLOW CURVES (WATER) FOR TOYOPEARL AF-rPROTEIN A HC-650F IN A QS 200 COLUMN AT VARIOUS BED HEIGHTS

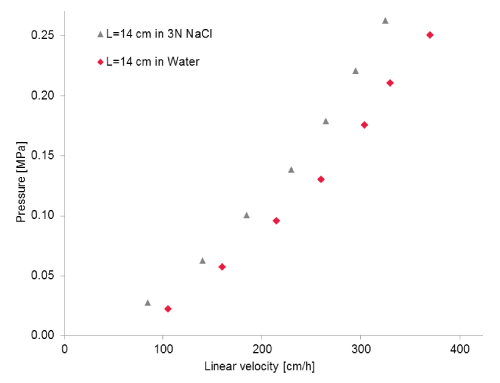

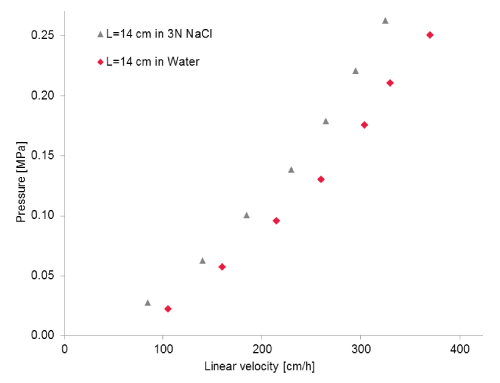

Figure 2 shows a comparison of the pressure flow curve for water at 14 cm bed height and 3 M NaCl, which was used to mimic the viscosity of a mAb feedstock.

FIGURE 2_COMPARISON OF PRESSURE FLOW CURVES (WATER VS. 3 N NACl) FOR TOYOPEARL AF-rPROTEIN A HC-650F AT 14 cm BED HEIGHT IN QS 200

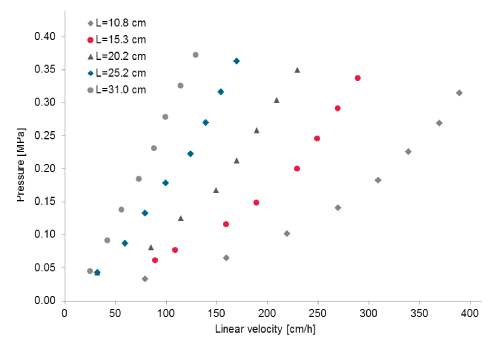

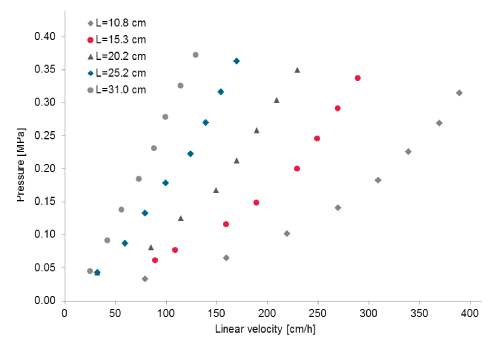

Packing experiments with a 40 cm ID Resolute columns show that at a bed height of about 15 cm is ideal to run at a residence time of 3 min minimum (with linear flow rates between 200 and 250 cm/h). Figure 3 shows pressure flow curves in water as mobile phase for various bed heights for the 40 cm ID Resolute column.

FIGURE 3_PRESSURE FLOW CURVES (WATER) FOR TOYOPEARL AF-rPROTEIN A HC-650F IN A RESOLUTE 400 COLUMN AT VARIOUS BED HEIGHTS

In the CA-601S radial flow column from Proxcys TOYOPEARL AF-rProtein A-650F HC compresses ~22 % in water. A 28 % excess of the resin is recommendable to fill the column. The tests performed in water yielded reproducible plate numbers of 3,500 N/m and symmetry values of 1.1. Pressure at 1.3 minutes residence time was 0.12 MPa. Packing in 1 N NaCl yielded 4.,500 N/m and Af=1.2, when 2 N NaCl was injected. The packed bed remained consistent at 1.5 minutes residence time in 1N NaCl at 0.12 MPa.

This demonstrates that this column type is suitable for capturing processes of mAb solutions at high flow rates/short residence times.

CONCLUSION

TOYOPEARL AF-rProtein A HC-650F can be used in a variety of process column types. Its small particle diameter of 45 µm contributes to the high binding capacities of up to 100 g/L for IgG. At the same time it requires balancing flow rate and bed height to obtain best results. To fully exploit the fast adsorption kinetics of TOYOPEARL AF-rProtein A HC-650F it is favorable to use short bed heights with fast flow rates/short residence times. This is easily applicable in radial flow columns.

Other than the column types, dimensions and system setups described here, might require the adaption of the proposed conditions to the respective pressure specifications. Ask our experienced Technical Support Team to support your individual column packing approach.

To screen and optimize method parameters the resin is also available in prepacked ToyoScreen®, RoboColumn® and 5 mL MiniChrom format. Larger prepacked columns with TOYOPEARL AF-rProtein A HC-650M can be supplied in cooperation with Atoll GmbH, Weingarten.

TOSOH

Application n°a15p64a

TOYOPEARL AF-rProtein A HC is an ultra-high capacity resin for affinity purification of immunoglobulins. Particle size, porosity of the base material, as well as ligand composition and density was optimized with the aim to reach maximum binding capacity. The resulting resin offers a typical binding capacity of 70 g/L resin at 5 minutes residence time. The binding capacity is only slightly decreased when reducing the residence time/increasing linear flow.

The high binding capacity of the resin at short residence times allows using short bed heights and high flow rates. However, due to the relatively small particle size of 45 µm flow rates need to be adapted to the pressure limitations of the system/column hardware.

In order to determine the optimum conditions for packing and using this resin in process scale columns we evaluated conditions for various column dimensions and manufacturers.

MATERIAL AND METHODS

COLUMN HARDWARE:

A: 20 cm ID Quikscale® (QS 200), 10 µm mesh size, max.0.6 MPa, MerckMillipore

B: 40 cm ID Resolute® 400 self-packer, 20 µm mesh size, max. 0.5 MPa, Pall Corporation

C: CA-601S radial flow column with 6 cm bed height, 5 L bed volume, 10 µm mesh size, Proxcys B.V.

PACKING PROCEDURE

A (QS 200): Slurry concentration 40 - 50 %; Packing was performed according to the TOYOPEARL Instruction Manual:

Flow was increased stepwise, starting with 50 cm/h over 100 cm/h to 200 cm/h before lowering the piston to the top of the bed. For final bed compression the flow was increased stepwise again starting from 100 cm/h to 300 cm/h (or reaching max. 0.4 MPa) before lowering the piston 2 - 3 mm into the final bed.

B (Resolute 400): Slurry concentration: 30 - 40 %; Slurry transfer was performed with a diaphragm packing pump into the column at constant ~0.45 MPa pneumatic pressure. The packing speed of initially ~2,000 cm/h went down to 100 cm/h during bed formation. Flow packing: stepwise flow increase with process pump (∆50 cm/h/min until max system pressure). Piston was lowered 2 mm into the bed.

C (CA-601S): Slurry concentration 30 - 50 %; Slurry transfer and packing with system pump into the column (∆p~0.3 MPa); packing speed ~600 cm/h.

COLUMN TESTING

Bed stability was tested in water, 1 M NaCl and 3 M NaCl (to mimic mAb feedstock application) as a mobile phase. Packing performance was evaluated by injecting 50 mL of 5 % acetone (UV detector) or salt (conductivity detector) at 100 cm/h.

RESULTS

Table 1 shows optimal flow rates/residence times for various bed heights in a 20 cm ID QuikScale column. Up to a bed height of 15 cm a residence time of up to 2 -3 min is feasible. For higher bed heights such as 20 cm the residence time should be increased to > 5 minutes which simultaneously allows exploiting the maximum binding capacity of the resin.

Packing qualities of 4,000 - 6,000 theoretical plates per meter for the unretained peak and symmetry values of 1.1 – 1.7 were obtained throughout all packing tests at various bed heights (~ 20 different experiments in total).

TABLE 1_FLOW RECOMMENDATIONS FOR VARIOUS BED HEIGHTS

Figure 1 shows the pressure flow curves in water as mobile phase for various bed heights for the 200 mm ID QuickScale column.

FIGURE 1_PRESSURE FLOW CURVES (WATER) FOR TOYOPEARL AF-rPROTEIN A HC-650F IN A QS 200 COLUMN AT VARIOUS BED HEIGHTS

Figure 2 shows a comparison of the pressure flow curve for water at 14 cm bed height and 3 M NaCl, which was used to mimic the viscosity of a mAb feedstock.

FIGURE 2_COMPARISON OF PRESSURE FLOW CURVES (WATER VS. 3 N NACl) FOR TOYOPEARL AF-rPROTEIN A HC-650F AT 14 cm BED HEIGHT IN QS 200

Packing experiments with a 40 cm ID Resolute columns show that at a bed height of about 15 cm is ideal to run at a residence time of 3 min minimum (with linear flow rates between 200 and 250 cm/h). Figure 3 shows pressure flow curves in water as mobile phase for various bed heights for the 40 cm ID Resolute column.

FIGURE 3_PRESSURE FLOW CURVES (WATER) FOR TOYOPEARL AF-rPROTEIN A HC-650F IN A RESOLUTE 400 COLUMN AT VARIOUS BED HEIGHTS

In the CA-601S radial flow column from Proxcys TOYOPEARL AF-rProtein A-650F HC compresses ~22 % in water. A 28 % excess of the resin is recommendable to fill the column. The tests performed in water yielded reproducible plate numbers of 3,500 N/m and symmetry values of 1.1. Pressure at 1.3 minutes residence time was 0.12 MPa. Packing in 1 N NaCl yielded 4.,500 N/m and Af=1.2, when 2 N NaCl was injected. The packed bed remained consistent at 1.5 minutes residence time in 1N NaCl at 0.12 MPa.

This demonstrates that this column type is suitable for capturing processes of mAb solutions at high flow rates/short residence times.

CONCLUSION

TOYOPEARL AF-rProtein A HC-650F can be used in a variety of process column types. Its small particle diameter of 45 µm contributes to the high binding capacities of up to 100 g/L for IgG. At the same time it requires balancing flow rate and bed height to obtain best results. To fully exploit the fast adsorption kinetics of TOYOPEARL AF-rProtein A HC-650F it is favorable to use short bed heights with fast flow rates/short residence times. This is easily applicable in radial flow columns.

Other than the column types, dimensions and system setups described here, might require the adaption of the proposed conditions to the respective pressure specifications. Ask our experienced Technical Support Team to support your individual column packing approach.

To screen and optimize method parameters the resin is also available in prepacked ToyoScreen®, RoboColumn® and 5 mL MiniChrom format. Larger prepacked columns with TOYOPEARL AF-rProtein A HC-650M can be supplied in cooperation with Atoll GmbH, Weingarten.