|

- 4 independent zones

- Magnetic and overhead stirring

- -30 °C to +180 °C

- 2 ml to 400 ml vessels

- Software control

|

|

Overview

|

|

|

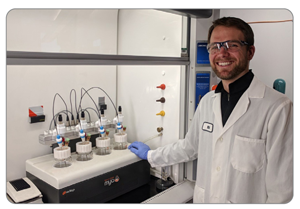

A flexible tool for a wide range of applications, from discovery chemistry to process development

|

| |

|

|

|

| |

|

|

Flexible and versatile

|

|

|

- 4 different temperature zones, each with heating and active cooling

- Use one compact system for a range of experiments

- Precise temperature control

- Magnetic or optional overhead stirring

- Accepts a wide range of vessel sizes and styles

- Control your experiments and log results automatically

- Use Mya 4 with or without a chiller

|

|

|

|

|

|

| |

Applications

|

| |

- Design of Experiment (DoE)

- Process development

- Scale up

- Route scouting

- Crystallisation studies

- Polymorph screening

- Biopharma research

- Lead optimisation

- Reaction optimisation

- Reagent, catalyst and solvent screening

|

| |

|

|

Safer, cleaner, greener and more productive

|

|

|

- Replace inefficient, messy and unsafe oil and ice baths

- Save space compared with separate reaction set-ups

- Software control improves safety, reduces manual errors, and allows 24/7 unattended chemistry, for improved productivity

- Create, repeat and share experiments and results with ease and accuracy

- Easily manage complex multi-step and multi-device experiments

- Integrates 3rd party devices such as pumps, balances and pH sensors etc.

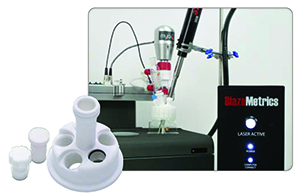

- TFE lids to hold 3rd party process analytical technology (PAT) such as Blaze Metrics.

|

|

|

| |

|

|

Mya 4 - Details

|

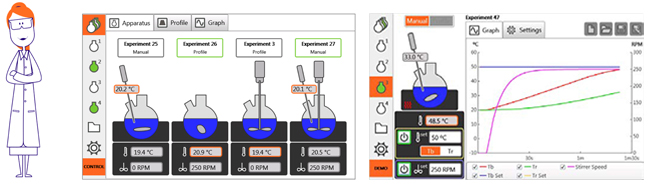

Precise temperature control of four independent zones with magnetic or overhead stirring

|

|

|

|

| |

4 reaction zones

|

| |

- Use 1, 2, 3 or 4 zones

- Operate zones in parallel or individually by multiple users

- Compact footprint 600 (W) x 360 (D) x 370 (H) mm

|

| |

|

| |

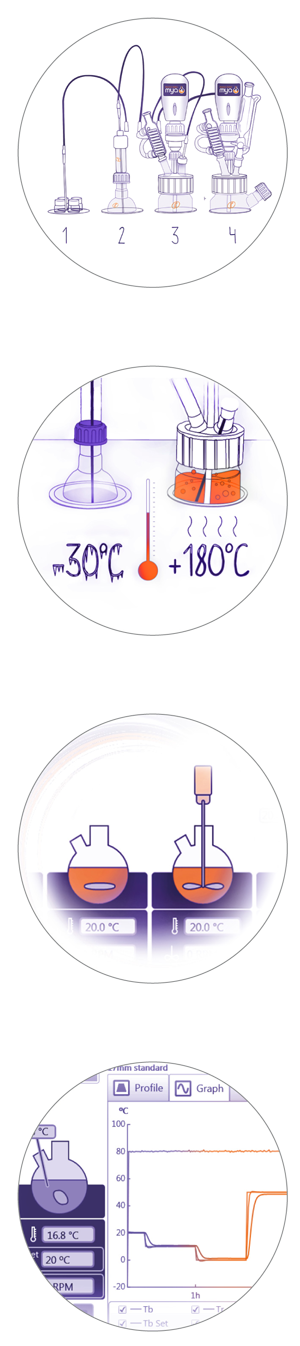

Precise temperature control

|

| |

Temperature range from -30 °C to +180 °C (block temperature)

- Providing a solution temperature of at least -20 °C to 150 °C

- Up to 200 °C difference between adjacent positions

- Control the temperature of each zone independently

- Choose to control by block or solution temperature

- Pt100 temperature probes available in stainless steel or PTFE encapsulated

|

| |

|

| |

Use Mya 4 with or without a chiller

|

| |

Mya 4 uses powerful Peltier technology to provide rapid cooling to -30 °C

- Peltier cells require tap or chilled water to dissipate heat

|

| |

|

| |

Peltier cooling source |

Tap water at 15 °C |

Chilled water at 5 °C |

| |

Minimum block temperature |

-25 °C |

-30 °C |

| |

Minimum solution temperature |

-20 °C |

-25 °C |

| |

|

| |

Magnetic or optional overhead stirring

|

| |

- Integrated magnetic stirring - from 100 to 1000 rpm

- Optional overhead stirring - from 100 to 1000 rpm

- Control the stirring speed of each position independently

- Use magnetic or overhead stirring in adjacent zones

|

| |

|

| |

|

| |

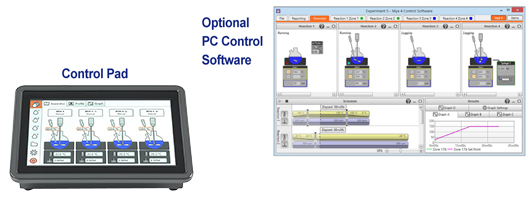

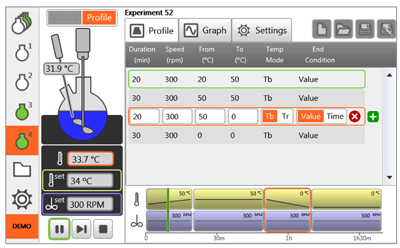

Software control and data logging

|

| |

Choice of Touch-screen Control Pad and PC Control Software

- Run experiments in manual or profile mode

- Easily repeat profiles

- Export CSV data

|

| |

|

|

| |

|

|

Glassware and accessories

|

|

|

Choose from a wide selection of vials, tubes, round bottom flasks and process vessels, from 2 ml to 400 ml

|

| |

|

|

Wide selection of vessel styles and volumes

|

|

|

Process reaction vessels:

- With straight sides and dished base to mimic jacketed reactors

- 50 ml, 100 ml, 150 ml, 250 ml and 400 ml

- Side arm option

- Baffled vessel options

|

|

| |

|

Round bottom flasks from the Carousel 6 Plus range:

- 25 ml, 50 ml, 100 ml and 250 ml

- One or two side arm options

- Standard and wide neck options

- Baffled vessel options

|

|

| |

|

Vials and tubes from 2 ml to 50 ml:

- 12 mm, 16 mm, 17 mm, 17 mm tapered, 24 mm, 1 inch and 28 mm diameters

- Radleys Carousel 12 Plus reaction tubes

|

|

| |

|

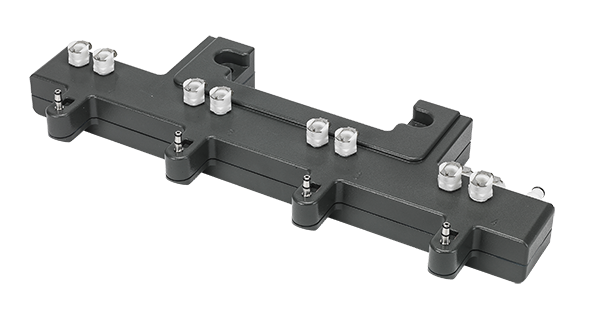

Aluminium Inserts

|

|

Removable anodised aluminium inserts for different size vessels

|

|

| |

|

Multi-neck lids

|

|

| For wide neck round bottom flasks and process vessels |

|

| |

|

PTFE lids

- 5 or 6-neck

- For improved durability and safety

- Stronger to support heavier probes/accessories

- 6-neck PTFE Blaze probe lid

|

|

| |

|

Glass lids

- 3 or 5-neck

- 3.3 Borosilicate glass

|

|

| |

|

Accessory glassware

|

|

|

| A wide range of dedicated glass accessories including: |

|

|

- Condensers

- Dropping funnels

- Solid addition funnels

- Stoppers

|

|

|

| |

|

|

Head options - refluxing & glassware support

|

Choose from three different Mya 4 heads to suit your chemistry needs. Easy to set up and no tools required.

|

| |

|

|

|

|

|

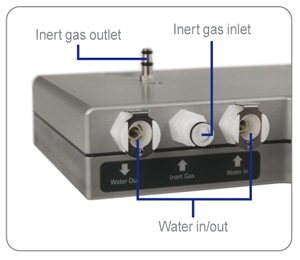

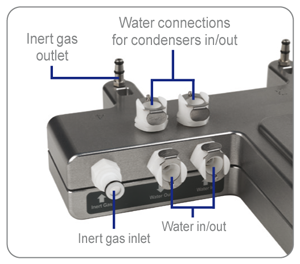

Manifold Head

|

|

| |

Provides cooling water to glass condensers and distributes inert gas

|

| |

- Required when using multi-neck lids

- All the water connections have shut-off valves - no mess

- Note: Glassware with reflux tubes can be used but not for refluxing

|

| |

|

|

| |

Reflux Head

|

| |

Cools reflux tubes and distributes inert gas

|

| |

- Can be used with reflux tubes (or wide neck reflux tubes) and short tubes/vials

- Note: Can be used with overhead stirrers

|

| |

|

|

| |

Support Head

|

|

| |

Choose the Support Head if you want to use different glassware and accessories such as:

|

| |

- Findenser and Findenser Mini

- Traditional glass condensers

- Non-standard flasks and tubes

- Soxhlet extraction glassware

- Probes and sensors

- Use with StarFish gas and water manifold

|

| |

|

|

|

Customer testimonials

|

|

|

Accurate temperature control achieving big results, on a small scale

|

|

|

| |

|

|

Mya 4 applications which require accurate temperature control:

|

|

|

- Exothermic reactions - which require active cooling

- Study of parameters other than temperature - which require reliable and reproducible temperatures

- Working with temperature-sensitive materials (e.g. biomolecules) - which require tightly controlled temperatures

- Experiments requiring slow cooling or heating ramps

|

|

|

| |

|

|

Johnson Matthey - Macfarlan Smith, API manufacturer

|

|

|

Study of key processing parameters other than temperature

|

|

´The precise temperature control provided by the Mya 4 has been essential to understanding key processing parameters of temperature sensitive experiments. It has allowed us to improve our understanding of current manufacturing processes."

" Without accuracy of temperature, you cannot conduct a successful design of experiment (DoE) exercise."

Dr Timothy Davies, Senior Development Chemist |

|

| |

|

|

Opioid manufacturer

|

|

|

Carefully controlled cooling ramps for crystallisation optimisation

|

|

"Prior to acquiring Mya 4, we used stirring hotplates and liquid cooling baths (dry ice/acetone) when needed. The set up and tinkering using this regime was completely obviated with Mya 4, which is basically a walk up reaction workstation."

"We do a lot of reaction optimisation work (different catalyst loads, different temperatures, etc.) and recently had to do a crystallisation optimisation that required carefully controlled cooling ramps – all of this was a breeze with Mya 4 and made our research progress much quicker."

Senior Process Development Chemist |

|

| |

|

|

Purolite Life Sciences, Resin manufacturer

|

|

|

Temperature-sensitive materials and exothermic reactions

|

|

´Mya 4 fulfils the need of a multipurpose small-scale reactor system that is not overspecified. The fact that the unit is so versatile is a strong advantage.´

´On previous systems I have looked at, flask sizes were limited to only one or two options.

I would have loved a Mya 4, two years ago so I could have used it as the workhorse for most of the project.´

Dr Patrick Gilbert, R&D Manager |

|

| |

|

|

| |

|

|

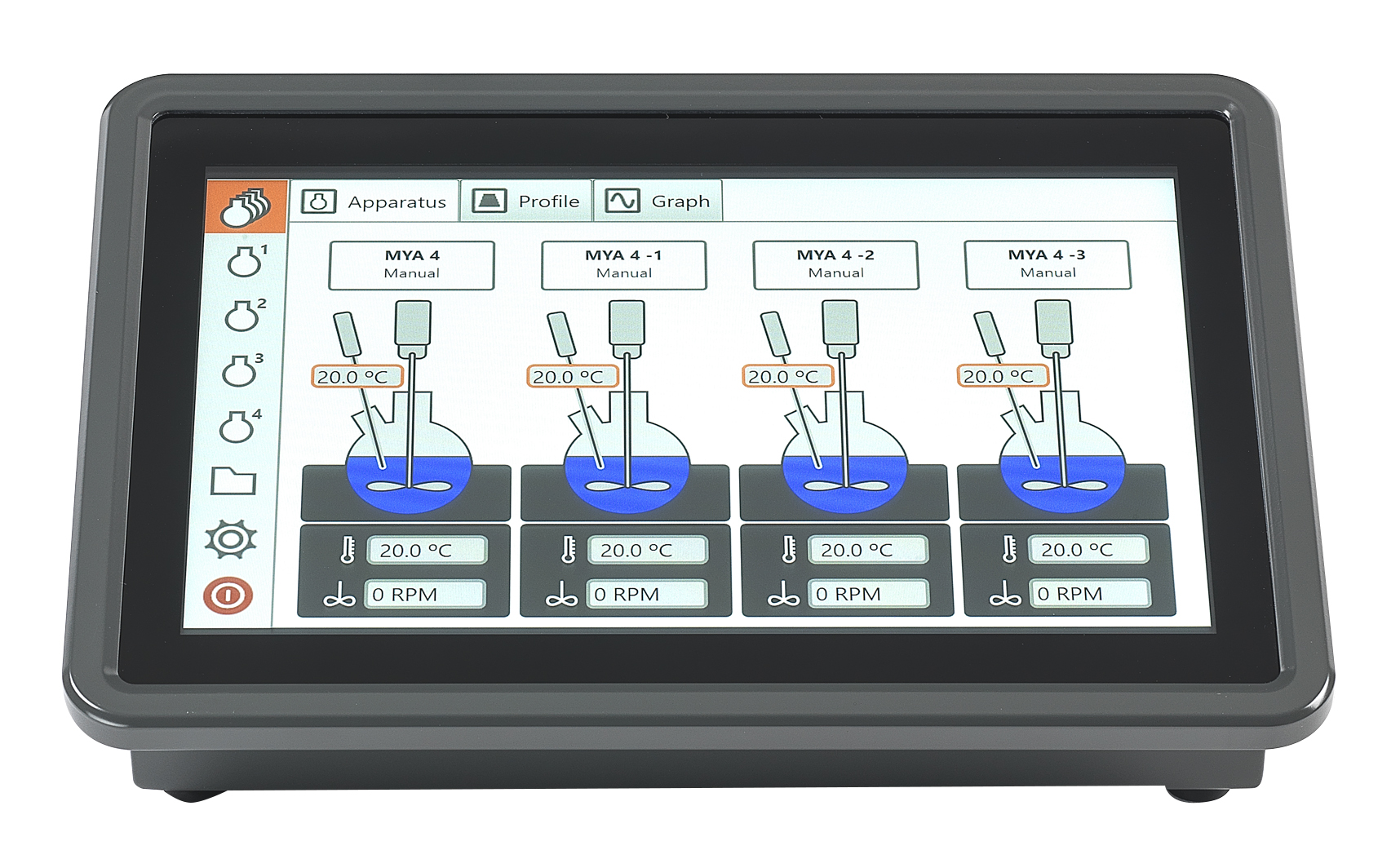

Mya 4 Control Pad

|

|

|

Unattended chemistry 24/7 with software control for improved productivity, safety and reduced manual errors

|

| |

|

|

Touch-screen Control Pad

|

|

|

|

|

|

- Supplied as standard with Mya 4

- Set automated profiles or use manual control

- Intuitive and easy to use

- Compact footprint with large 10" display

|

|

|

| |

|

|

Control Options

|

| The touch-screen Control Pad requires minimal training. It will control and log heating/cooling and stirring for all four zones independently. Repeating experiments and exporting data is a breeze. |

| |

|

|

Upgrade to the Mya 4 PC Control Software if you also want to:

|

- Integrate 3rd party devices e.g. pumps and pH meters

- Create profile experiments with any number of steps

- Increase safety by using warnings, safe states and shut down settings

- Create a comprehensive report in a few clicks at the end of your experiment

|

| |

|

|

| Features |

Control Pad |

PC Software |

| Intuitive and easy to use touch-screen control |

✔ |

✖ |

| Compact footprint - fumehood compatible |

✔ |

✖ |

| Maximum 10 steps of 16 hours each |

✔ |

✖ |

| Multi-user - independently run experiment in 4 zones |

✔ |

✖ |

| Control and log the temperature and stirring of each zone independently |

✔ |

✔ |

| Set safety limits |

✔ |

✔ |

| Export experimental profiles and results in CSV via USB memory stick |

✔ |

✔ |

| Adjust parameters manually - using manual/direct mode |

✔ |

✔ |

| Create multi-step recipes - using profile/schedule mode |

✔ |

✔ |

| Flexibility to make and track on-the-fly adjustments to your experiment |

✔ |

✔ |

| Automatically log all data |

✔ |

✔ |

| Share experimental results and recipes with other users |

✔ |

✔ |

| View real-time graphs |

✔ |

✔ |

| Control and log up to 16 x 3rd party devices on one screen |

✖ |

✔ |

| Create complex experiments with any number of steps |

✖ |

✔ |

| Interlink devices and set feedback/control loops and end point conditions |

✖ |

✔ |

| Report Wizard creates detailed reports in RTF or export results in CSV |

✖ |

✔ |

| Log comments |

✖ |

✔ |

| Runs on a Windows laptop |

✖ |

✔ |

Mya 4 PC Control Software will control and log 3rd party devices

|

|

Control 3rd party devices

|

|

|

Mya 4 Control Software includes a library of pre-configured driver files allowing easy integration with a range of 3rd party devices.

|

| |

|

| |

|

| |

Data hub

|

| |

Using the Data Hub, Mya 4 Control Software can connect to, control and log data from multiple devices with an RS232 serial interface. |

| |

|

| |

|

|

How to configure your Mya 4 Reaction Station

|

|

|

Select the components you need to suit your chemistry Our experts can advise you on the best options for your application

|

| |

|

|

| 1 |

Stirring options

Select stirrer bars for magnetic stirring and/or Mya compact stirrers and stirrer shafts for overhead stirring. |

|

| |

|

|

| 2 |

Head options

Select a Manifold, Reflux or Support head. |

|

| |

|

|

| 3 |

Lids or reflux tubes

Glass or PTFE multi-neck lids. Standard or wide-neck reflux tubes. |

|

| |

|

|

| 4 |

Vessel styles & volumes

Select vessels: tubes, vials, round bottom flasks and process vessels from 2 ml to 400 ml. |

|

| |

|

|

| 5 |

Aluminium inserts

Select the appropriate insert for each vessel size.

|

|

| |

|

|

| 6 |

Select accessories

Temperature probes, funnels, condensers etc. |

|

| |

|

|

| 7 |

Control options

Select the optional Mya 4 PC Control Software, Data Hub and any 3rd party devices. |

|

| |

|

|

Mix & Match

|

|

|

A flexible reaction station with a wide range of options and accessories to fit your needs

|

|

|

|

| |

Reflux Head

|

| |

|

| |

|

| |

Manifold Head

|

| |

|

| |

|

| |

Applications

|

| |

- Design of Experiment (DoE)

- Process development

- Scale up

- Route scouting

- Crystallisation studies

- Polymorph screening

- Biopharma research

- Lead optimisation

- Reaction optimisation

- Reagent, catalyst

and solvent screening

|

Discover the system in video

|

| |

|

|

|